SPECIALITY PRINT FINISHES

What other printers can’t—or won’t—do, we do.

Wells & Drew runs the full spectrum under one roof—since 1855.

Contact Us Learn More

What is a Finish?

A finish changes how the piece feels and reads.

Ink can be flat or raised. Paper can be embossed or debossed. Foil adds reflectivity. Die cutting changes the shape.

No Vendor Handoffs. Cleaner Results.

Everything runs in-house. Faster answers. Fewer remakes.

Sharper detail. Consistent reorders.

Your brand signals premium—before anyone reads a word.

They notice the weight. The crisp edge. The clean impression.

Your materials look deliberate. They get handled. They get kept.

Intent, Not Decoration.

Don’t choose effects. Choose the message.

Trust. Precision. Authority. We match the process to that goal.

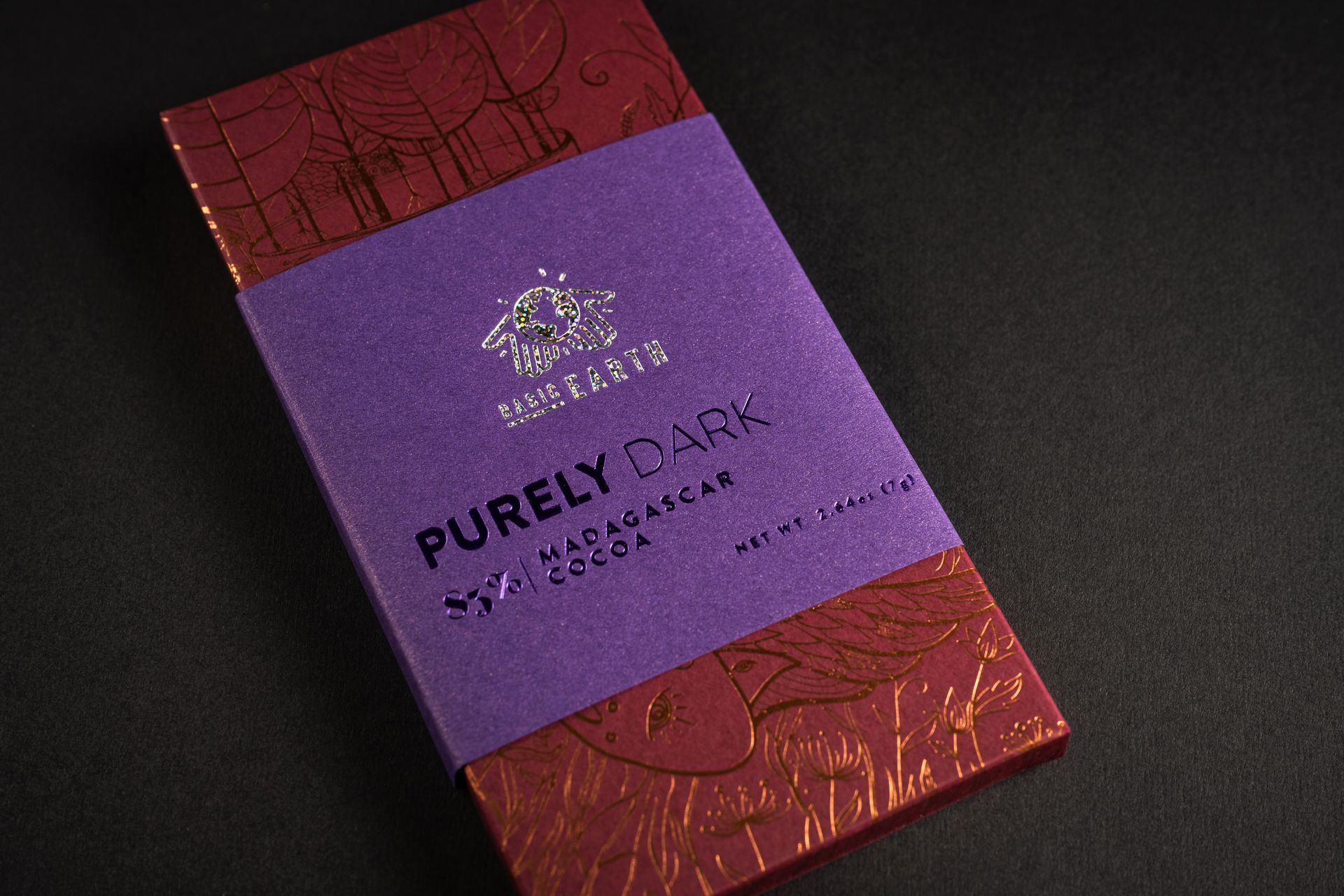

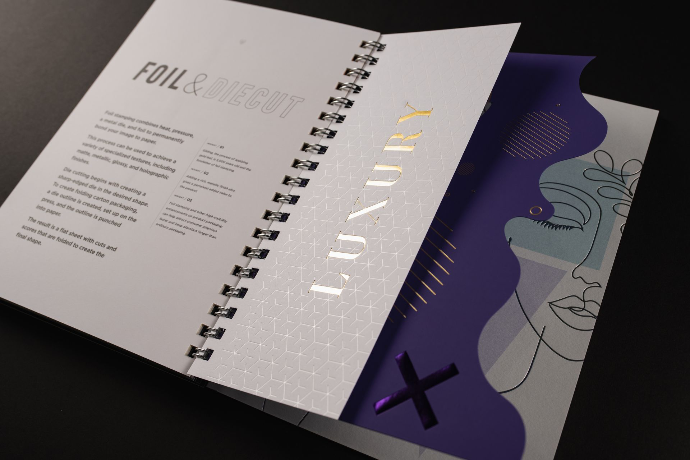

Foil

Light on command.

Foil reads as reflectivity—not ink. Hard edge. Clean contrast.

Best for: logos, seals, accents

A metal die, heat, and pressure bond foil to the sheet for a permanent mark.

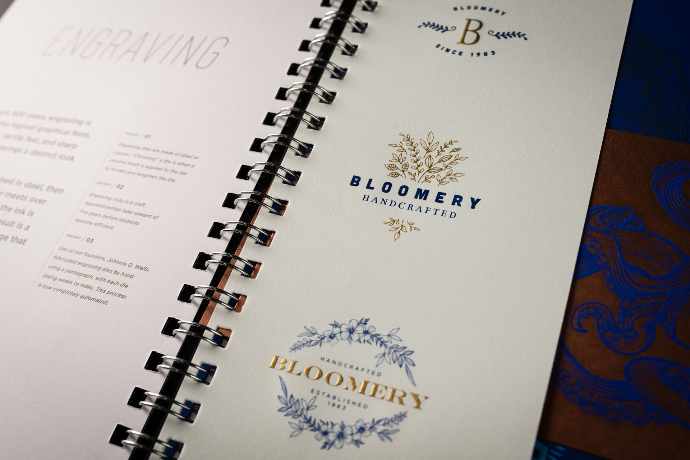

Engraving

Raised ink. Vivid color.

Ink rises in a ridge you can feel. Fine lines stay sharp.

Best for: crests, monograms, formal stationery

Engraving uses a metal plate and heavy pressure to create a raised ink edge with unmatched clarity.

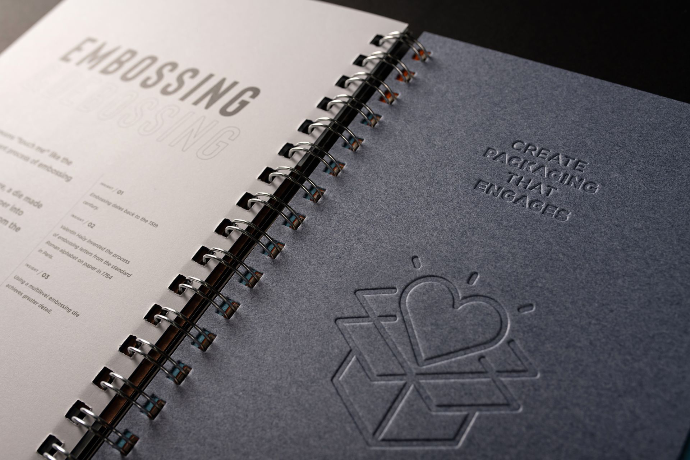

Embossing

Paper rises.

No ink required. Crisp shoulders. Real shadow and depth.

Best for: blind marks, borders, patterns

A matched die set forms the sheet into a raised impression—built to be felt.

Debossing

Paper sinks.

Recessed depth with clean edges. Quiet. Intentional.

Best for: minimalist logos, texture fields

A die presses the mark below the surface for a controlled, understated impression.

Diecut

Paper Shaped with steel.

Custom silhouettes—repeatable and clean. Die cuts are uniquely yours in the shape and design you specify.

Best for: packaging, cartons, tags, folders, inserts and covers.

Die cutting begins with creating a sharp-edged die in the desired shape. A die outline is created, set up on the press, and the outline is punched into paper.

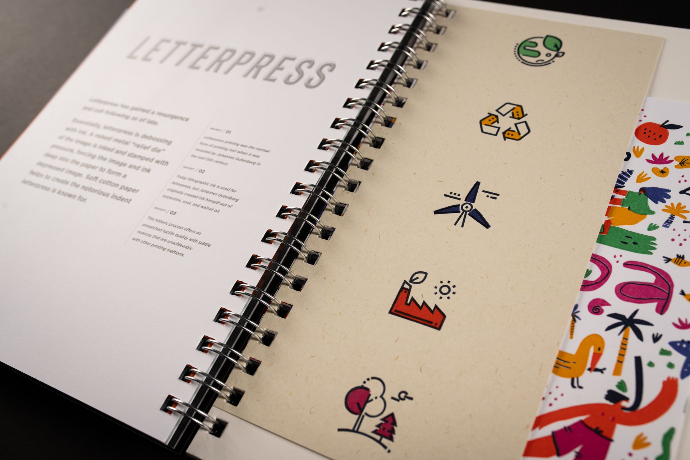

Letterpress

Ink with bite.

Dense ink with a measured impression into thick stock.

Best for: bold type, simple marks and invitations.

A raised plate inks the image, then presses it into the sheet for a tactile printed impression.

Soft cotton paper helps to create the notorious indent letterpress is known for.

Tell us the moment. We’ll recommend the finish.

Boardroom. Mail. Front desk. Compliance file. Send artwork if you have it. If you don’t, send the goal.

Choose Your Outcome

Showcase

From restrained precision to deliberate impact, each piece demonstrates how specialty finishes change how packaging is seen—and handled.

Ready to Make an Impact?

We don’t just offer packaging, we collaborate with you to create the perfect package for your brand. Our process ensures every element matches your vision.

From paper color to printing techniques, we guide you through the creative journey to achieve the perfect packaging solution.