Premium Packaging.

Small Quantities.

Wells & Drew is one of the few companies in the country offering short-run folding cartons with luxury finishes.

We don't compromise quality nor impact. Now that's a Nice Package.

See It. Feel It. Get the Sample Book. Learn MoreSize Doesn't Matter.

High-end packaging, now accessible without the need for massive quantities.

Specialty Techniques for Small Quantities

Get luxury finishes like engraving, embossing, and vivid color—even in small runs. Perfect for brands that want the premium look but need flexibility in order sizes.

Endless Combinations

With countless combinations of paper colors and printing techniques, the creative possibilities are endless. Each package is tailored to your brand, giving you full creative control.

Tailored Packaging Solutions

Packaging designed to reflect your brand’s identity. From paper to finish, every detail is custom-tailored to make your packaging truly unique.

Specialty Printing Techniques

Offering exclusive specialty printing processes like engraving, embossing, raised print, and vivid color—techniques that set your packaging apart.

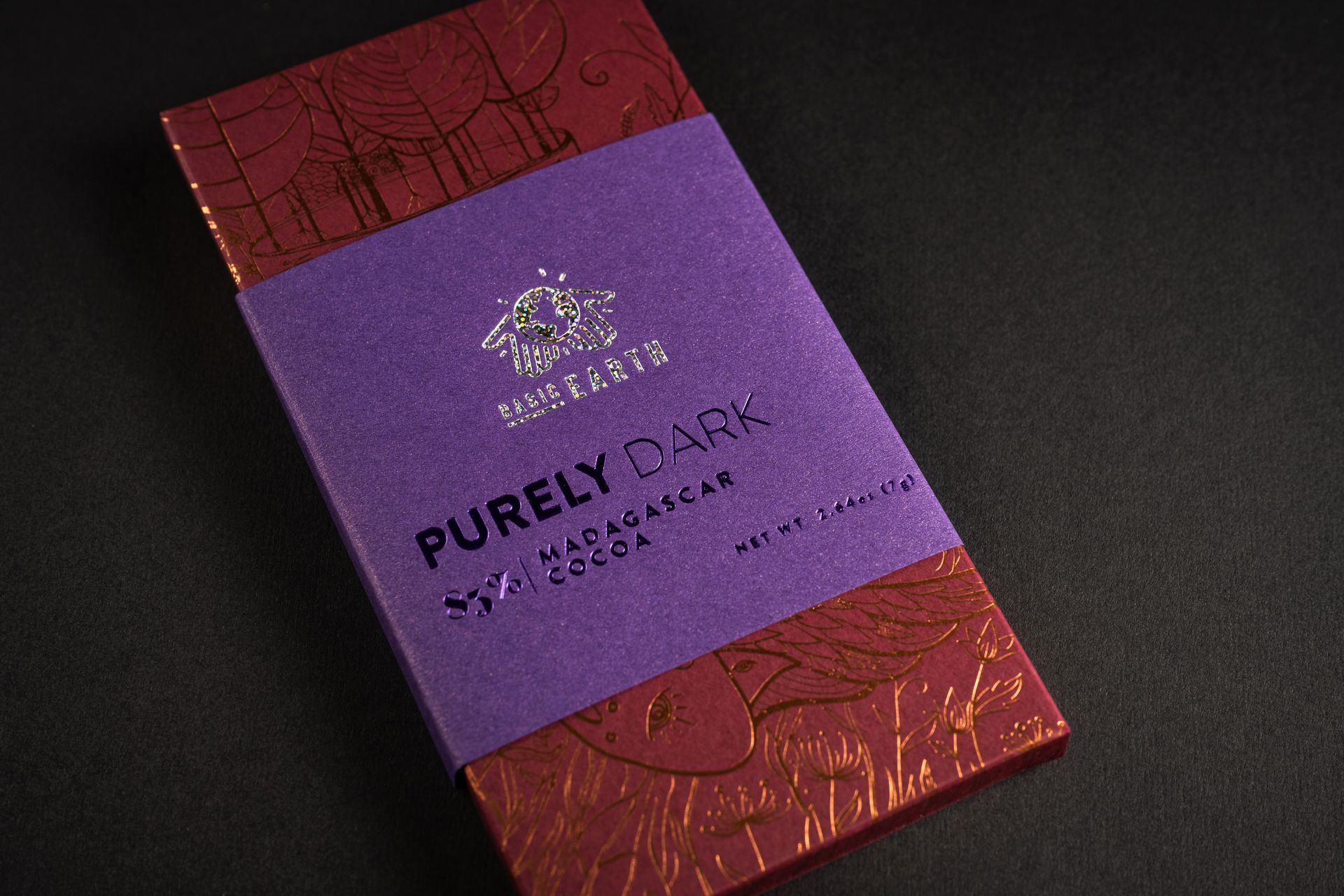

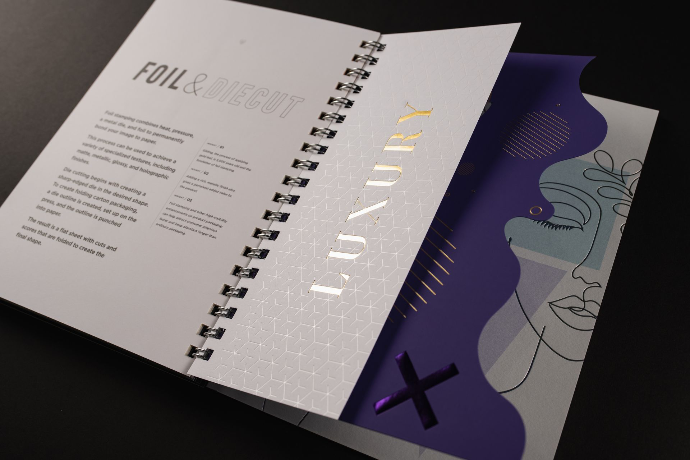

Foil

Let it shimmer and shine

Foil stamping combines heat, pressure, a metal die, and foil to permanently bond your image to paper.

This process can be used to achieve a variety of specialized textures, including matte, metallic, glossy, and holographic finishes.

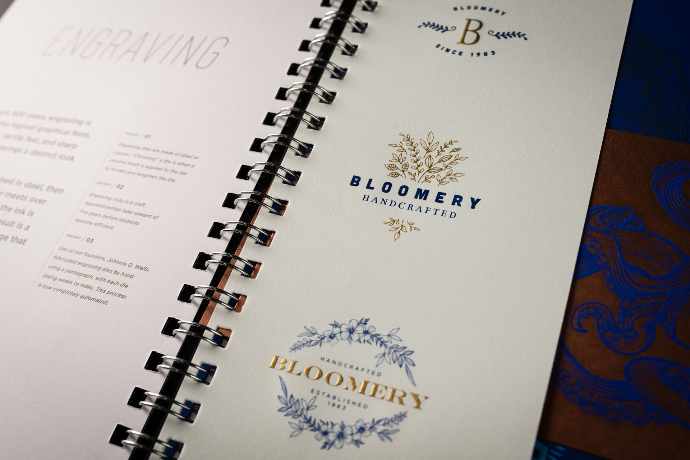

Engraving

Elevate your packaging and brand

Dating back 600 years, engraving is revered as the highest graphical form. Brilliant color, tactile feel, and sharp edges give engravings a distinct look and touch.

The design is first etched in steel, then ink fills the cavity. Paper meets over two tons of pressure, and the ink is raised from the page. The result is a tactile, three-dimensional image that is the mark of excellence.

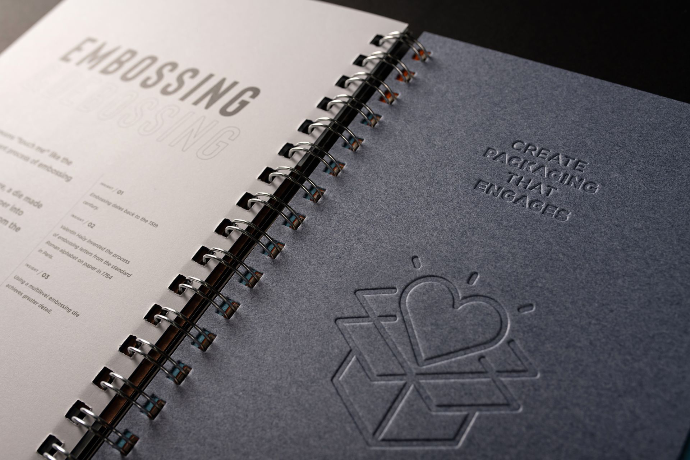

Embossing

Packaging with impression

Nothing screams “touch me” like the artful and elegant process of embossing – no ink required.

Under one ton of pressure, a die made of magnesium forces the paper into the die, elevating your image from the surface of the sheet. The result: a three-dimensional shape and feel to your image that consumers cannot resist touching.

Debossing

Design with depth

While embossing raises your design, debossing takes the opposite approach, creating a sunken relief in your material. With a similar application of heavy pressure and a die, debossing presses your image below the surface, adding a subtle yet sophisticated tactile dimension that demands attention.

The result: an indented design that invites interaction and elevates your packaging with understated elegance.

Diecut

Packaging that’s as unique as your product

Die cutting begins with creating a sharp-edged die in the desired shape. To create folding carton packaging, a die outline is created, set up on the press, and the outline is punched into paper.

The result is a flat sheet with cuts and scores that are folded to create the final shape.

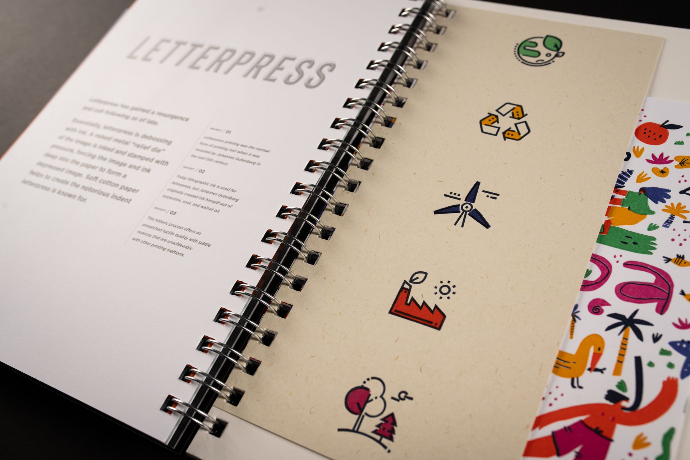

Letterpress

Impressive packaging

Letterpress has gained a resurgence and cult following as of late.

Essentially, letterpress is debossing with ink. A raised metal “relief die” of the image is inked and stamped with pressure, forcing the image and ink deep into the paper to form a depressed image. Soft cotton paper helps to create the notorious indent letterpress is known for.

Showcase of Design Excellence

See the impact of our packaging in action. Whether you’re looking for minimal sophistication or bold contrast, our packaging offers an experience that both connects and persuades.

Ready to Make an Impact?

We don’t just offer packaging, we collaborate with you to create the perfect package for your brand. Our process ensures every element matches your vision.

From paper color to printing techniques, we guide you through the creative journey to achieve the perfect packaging solution.